Scaffolding & Formwork

Manufacturer and Solutions Provider

With over 40 years of expertise, SCAFFCO has become a leading manufacturer of scaffolding and formwork solutions for sectors like Construction, Infrastructure, Oil & Gas, and Industrial. Founded in 1980 as an agent for renowned scaffolding brands, we have grown into a robust manufacturing network serving the GCC, Africa, and Europe. Our advanced facilities in JAFZA, Dubai, and Mussafah ICAD1, Abu Dhabi, span over 50,000 square meters and feature cutting-edge robotic production units and stringent quality control processes, producing more than 50,000 tons of premium products each year.

SCAFFCO’s manufacturing capabilities include robotic arm welding, CNC machining, threading, and conveyor painting lines, allowing us to deliver versatile, high-quality solutions tailored to each project’s unique needs. Our full-service support—from design and pre-assembly to installation, training, and inspection—demonstrates our commitment to excellence and our proven track record on landmark projects across multiple regions.

Our Manufacturing Capabilities

At SCAFFCO, we are committed to excellence in quality, safety, and sustainability. Our standards ensure top-tier products, a secure environment for our team and customers, and a cleaner, safer world. We strive to exceed expectations, building trust through reliable, high-quality service in every project.

01

Robotic Arm Welding

Automated precision welding with robotic arms to ensure consistent quality across high-volume scaffolding components

02

Semi-Automatic Welding

Combines automation and skilled welding to enhance productivity and precision in manufacturing complex structures

03

Welding Stations

Dedicated welding areas equipped for custom fabrication and assembly of scaffolding elements with high durability

04

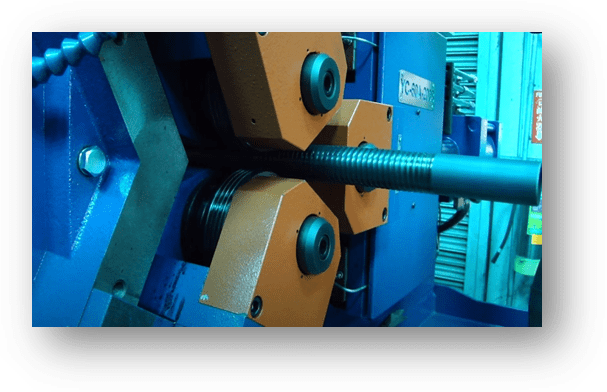

Threading

Specialized threading for secure, reliable joint assembly in formwork and scaffolding systems

05

CNC

Advanced CNC machining for high-precision cuts and shapes, crucial for scaffolding parts that require exact specifications

06

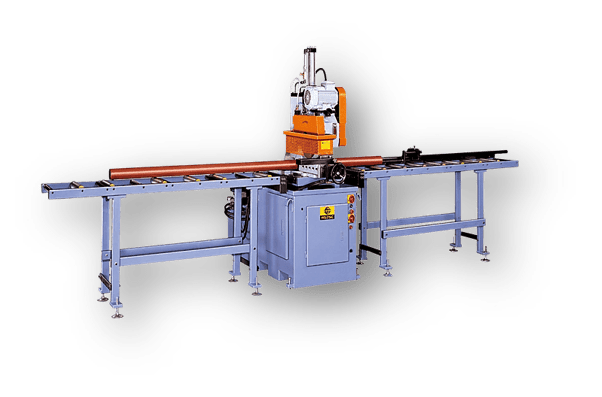

Cutting

High-quality cutting solutions to deliver precise component sizes that meet specific project requirements

07

Drilling

Precision drilling processes for accurate hole placement in scaffold and formwork components

08

Slotting

Accurate slotting for enhanced assembly compatibility and improved structural integrity of scaffolding products

09

Auto Shearing

Automated shearing technology for quick, uniform cuts on large volumes of metal, boosting production efficiency

10

Conveyor Painting Line

Continuous conveyor painting to provide durable, weather-resistant finishes on scaffolding products

11

Pressing

Pressing technology to shape and reinforce metals, adding strength to scaffolding and formwork components

12

Roll Forming

Roll forming processes to create custom shapes that increase the load-bearing capacity of scaffolding systems

Our end-to-end manufacturing solutions provide our clients with efficient, safe, and high-quality products, backed by a team committed to operational excellence and innovation. Partner with SCAFFCO and experience the advantage of advanced manufacturing tailored to the unique demands of your projects.

Our Manufacturing Capabilities

At SCAFFCO, we are committed to excellence in quality, safety, and sustainability. Our standards ensure top-tier products, a secure environment for our team and customers, and a cleaner, safer world. We strive to exceed expectations, building trust through reliable, high-quality service in every project.

Robotic Arm Welding

Automated precision welding with robotic arms to ensure consistent quality across high-volume scaffolding components

Semi-Automatic Welding

Combines automation and skilled welding to enhance productivity and precision in manufacturing complex structures

Welding Stations

Dedicated welding areas equipped for custom fabrication and assembly of scaffolding elements with high durability.

Threading

Specialized threading for secure, reliable joint assembly in formwork and scaffolding systems.

CNC

Advanced CNC machining for high-precision cuts and shapes, crucial for scaffolding parts that require exact specifications.

Cutting

High-quality cutting solutions to deliver precise component sizes that meet specific project requirements.

Drilling

Precision drilling processes for accurate hole placement in scaffold and formwork components.

Slotting

Accurate slotting for enhanced assembly compatibility and improved structural integrity of scaffolding products.

Auto Shearing

Automated shearing technology for quick, uniform cuts on large volumes of metal, boosting production efficiency.

Conveyor Painting Line

Continuous conveyor painting to provide durable, weather-resistant finishes on scaffolding products.

Pressing

Pressing technology to shape and reinforce metals, adding strength to scaffolding and formwork components.

Roll Forming

Roll forming processes to create custom shapes that increase the load-bearing capacity of scaffolding systems.

Our end-to-end manufacturing solutions provide our clients with efficient, safe, and high-quality products, backed by a team committed to operational excellence and innovation. Partner with SCAFFCO and experience the advantage of advanced manufacturing tailored to the unique demands of your projects.